Tinplate Low Speed Handpiece - digital 3D printed model for implant work – Foo Tian

Tinplate Low Speed Handpiece - digital 3D printed model for implant work – Foo Tian Detail:

The digital revolution is changing dentistry. Conventional manual methods are rapidly being replaced by new, precision digital technology and the benefits to your business and clients are many.

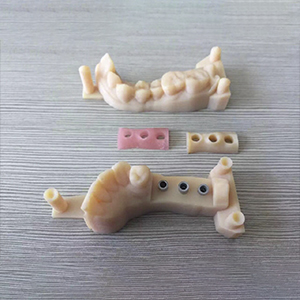

Traditional processes are slow and there is always the potential for human error. With digitally designed and manufactured prosthetic implants, crowns & bridges, milled splints or precision attachments – you will receive products that are consistent, reliable and accurate to the micron.

Intricate implant work will be simpler as they will fit with more ease, saving clinical time, cost and minimising patient anxiety. Digital manufacture also removes the risk of contaminants so the likelihood of fractures and cracking is almost negligible.

The benefits

The use of digital technology offers more in terms of solution options, cost savings and operational efficiencies for your practice. It also provides your patients with a more convenient, highly accurate and less invasive service.

Digital fabrication using 5-axis milling technologyDigital 3D scanning and CAD/CAM software – allowing a precise design and fitVersatility in material – including the fabrication of aesthetically preferred zirconia crownsSpeed and accuracy of digital impression technology enables fast patient treatment and resultsElectronic storage of impressions and record keepingMinimal need for adjustments – less patient time in the chairIncreased patient acceptanceLess likelihood of the restoration failingNo contaminants

We stay up to date with the latest in technological advancements to remain a leader in the market and deliver you the quality solutions that you expect for your clients.

Product detail pictures:

Related Product Guide:

The importance of mock drills and office inspections | Cad/Cam System

Global Dental Cad/Cam Restoration System Market Insights, Forecast to 2024 | Ems Dental Ultrasonic Scaler

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Tinplate Low Speed Handpiece - digital 3D printed model for implant work – Foo Tian, The product will supply to all over the world, such as: Ireland , Stuttgart , Croatia , We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.