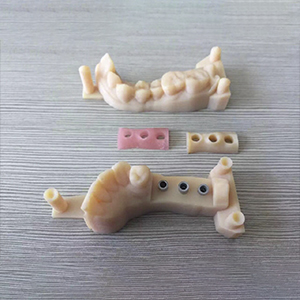

Tinplate Box Mini Implant - digital 3D printed model for implant work – Foo Tian

Tinplate Box Mini Implant - digital 3D printed model for implant work – Foo Tian Detail:

The digital revolution is changing dentistry. Conventional manual methods are rapidly being replaced by new, precision digital technology and the benefits to your business and clients are many.

Traditional processes are slow and there is always the potential for human error. With digitally designed and manufactured prosthetic implants, crowns & bridges, milled splints or precision attachments – you will receive products that are consistent, reliable and accurate to the micron.

Intricate implant work will be simpler as they will fit with more ease, saving clinical time, cost and minimising patient anxiety. Digital manufacture also removes the risk of contaminants so the likelihood of fractures and cracking is almost negligible.

The benefits

The use of digital technology offers more in terms of solution options, cost savings and operational efficiencies for your practice. It also provides your patients with a more convenient, highly accurate and less invasive service.

Digital fabrication using 5-axis milling technologyDigital 3D scanning and CAD/CAM software – allowing a precise design and fitVersatility in material – including the fabrication of aesthetically preferred zirconia crownsSpeed and accuracy of digital impression technology enables fast patient treatment and resultsElectronic storage of impressions and record keepingMinimal need for adjustments – less patient time in the chairIncreased patient acceptanceLess likelihood of the restoration failingNo contaminants

We stay up to date with the latest in technological advancements to remain a leader in the market and deliver you the quality solutions that you expect for your clients.

Product detail pictures:

Related Product Guide:

Global Dental Core Build-Up Materials Market 2019, Trend, CAGR Status, Growth, Analysis and Forecast to 2024 | Cad/Cam System

Manufacturing Intelligence: Hexagonâs CEO is the New King of CAM > ENGINEERING.com | Dental Composite Resin

We've been committed to offering easy,time-saving and money-saving one-stop purchasing support of consumer for Tinplate Box Mini Implant - digital 3D printed model for implant work – Foo Tian, The product will supply to all over the world, such as: Lisbon , UAE , Mauritania , We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.