Galvanized Iron Corrugated Steel Silicone Putty - digital 3D printed model for implant work – Foo Tian

Galvanized Iron Corrugated Steel Silicone Putty - digital 3D printed model for implant work – Foo Tian Detail:

The digital revolution is changing dentistry. Conventional manual methods are rapidly being replaced by new, precision digital technology and the benefits to your business and clients are many.

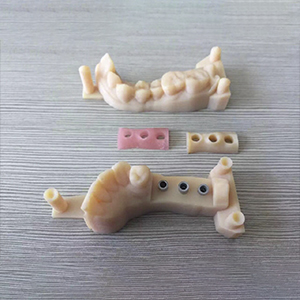

Traditional processes are slow and there is always the potential for human error. With digitally designed and manufactured prosthetic implants, crowns & bridges, milled splints or precision attachments – you will receive products that are consistent, reliable and accurate to the micron.

Intricate implant work will be simpler as they will fit with more ease, saving clinical time, cost and minimising patient anxiety. Digital manufacture also removes the risk of contaminants so the likelihood of fractures and cracking is almost negligible.

The benefits

The use of digital technology offers more in terms of solution options, cost savings and operational efficiencies for your practice. It also provides your patients with a more convenient, highly accurate and less invasive service.

Digital fabrication using 5-axis milling technologyDigital 3D scanning and CAD/CAM software – allowing a precise design and fitVersatility in material – including the fabrication of aesthetically preferred zirconia crownsSpeed and accuracy of digital impression technology enables fast patient treatment and resultsElectronic storage of impressions and record keepingMinimal need for adjustments – less patient time in the chairIncreased patient acceptanceLess likelihood of the restoration failingNo contaminants

We stay up to date with the latest in technological advancements to remain a leader in the market and deliver you the quality solutions that you expect for your clients.

Product detail pictures:

Related Product Guide:

Play it SMART: Silver diamine fluoride plus ITR for dental caries management in anxious pediatric patients | Cad/Cam System

Super-strong, bio-compatible material may make broken fillings a thing of the past | Ems Dental Ultrasonic Scaler

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Galvanized Iron Corrugated Steel Silicone Putty - digital 3D printed model for implant work – Foo Tian, The product will supply to all over the world, such as: belarus , Lyon , Luxemburg , Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!